Indication on remaining stabilization

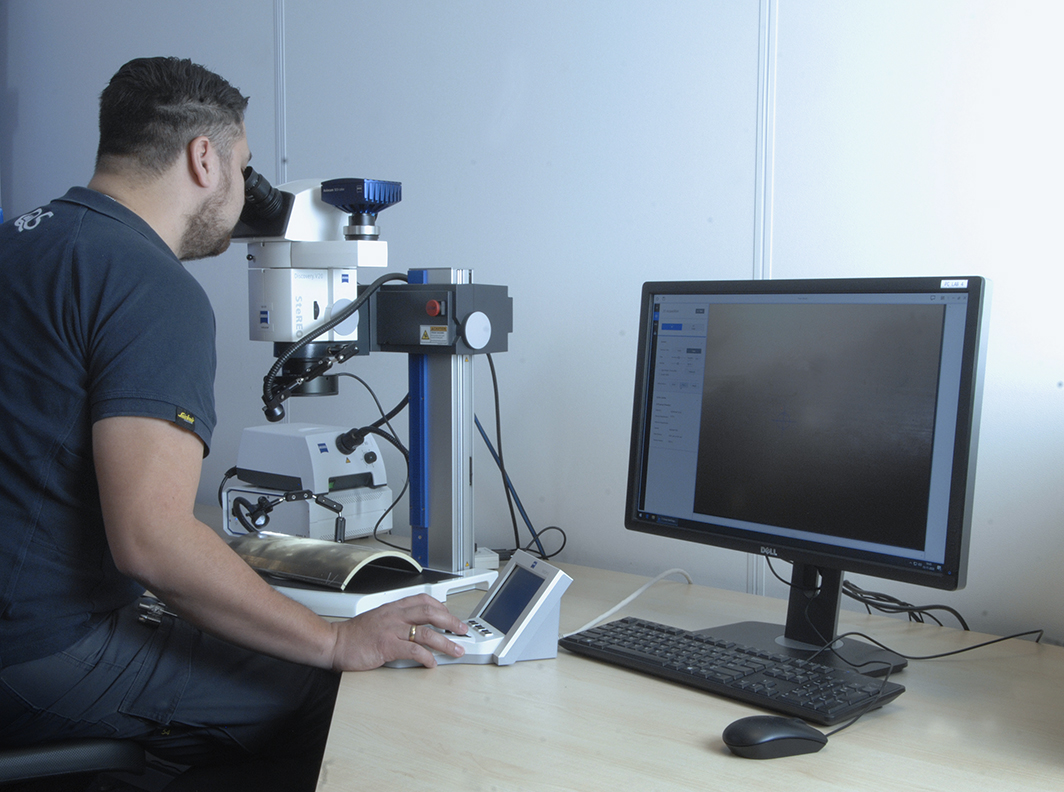

In our laboratory, we can perform completely independent measurements on test pieces from plastic products and plastic compounds. We do this according to various NEN, EN, ISO and ASTM test standards. Recently, we expanded our laboratory facilities with a DSC device for performing OIT measurements. This allows us to carry out the OIT measurement as part of a regular quality control or part of a (residual) life cycle assessment of PE (polyethylene) products, according to NEN-EN-ISO 11357-6, entirely in-house.

The abbreviation OIT stands for oxidation induction time. An OIT measurement is a standardised test in which the rate of oxidation heat release is determined using DSC (differential scanning calorimetry: differential heat measurement per unit time) followed by an extrapolation of the part of the curve with the largest heat release. Oxidation of PE material starts after the thermal stabiliser is consumed. The period (OIT value) between the start of time measurement and the onset of oxidation at 200 °C is calculated from the DSC measurement curve.

An OIT measurement is mainly performed in our laboratory on PE products such as pipes and geomembranes to determine resistance to oxidation. In combination with exposure to water and air at an elevated temperature, the measurement is used to determine the (residual) life span, for example to validate 100 years. The OIT measurement gives a quick indication of the remaining stabilisation against oxidation.

QS Testing is naturally pleased with the laboratory’s expansion to include OIT measurements. This allows us to carry out OIT measurements completely in-house, allowing us to switch even faster and (continue to) have a flexible way of working. In combination with the 17020 type A accreditation of our sister company QS Inspection in the field of sampling and construction and processing inspections, this allows QS to be the only party in the Netherlands to make a fully in-house statement about the expected life span of a foil construction.

Want to have an OIT measurement carried out for quality control purposes? Or a (residual) life span study to validate, say, a hundred years? Feel free to contact us. We will be happy to think along with you on your (tailor-made) problem.