Testing of plastics in compliance with current standards

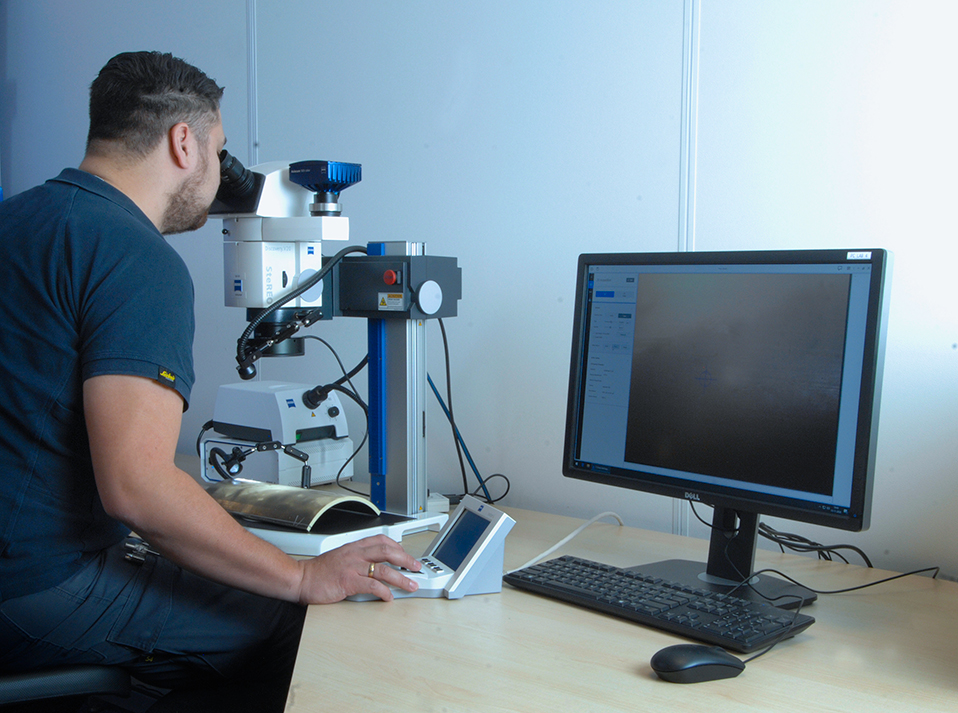

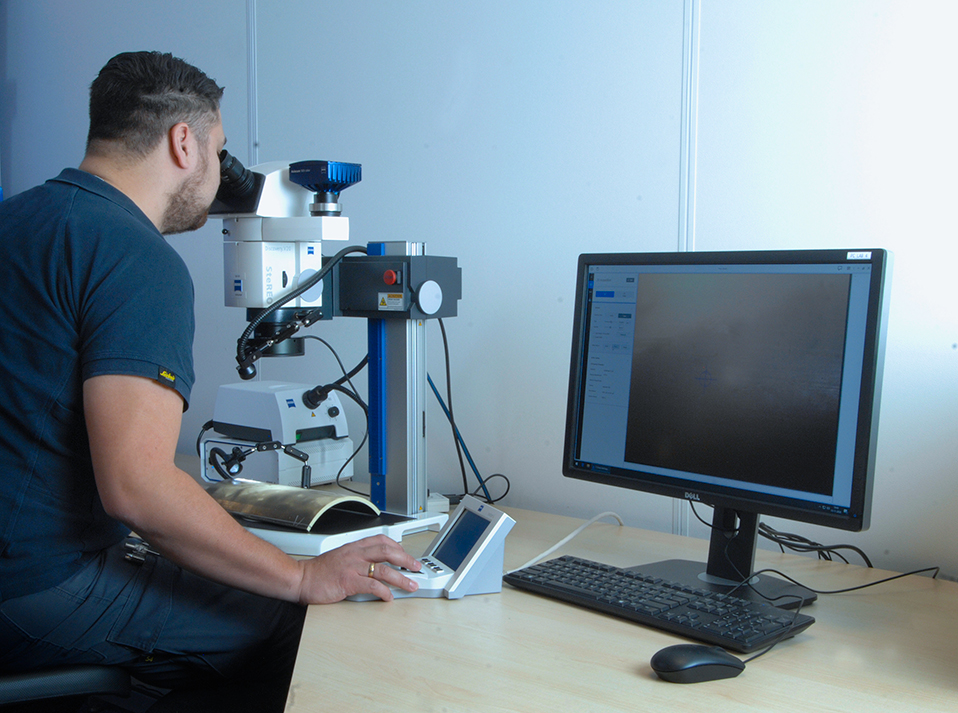

In our laboratory we can carry out completely independent research. Our laboratory facilities include a microscope for carrying out visual examinations at the microscopic prediction level. This allows us to carry out microscopic examination as part of a regular quality control, lifetime examination or as part of a damage investigation.

Microscopic examination is carried out in our laboratory in particular for the purpose of determining cracking in cross-sections and fracture surface analyses of test pieces on which a tensile, tensile stroke or detachment test has been carried out. The fracture surface analyses are to support measured crack expansion values and identification of the type of fracture or detachment.

In addition, microscopic research is used to clarify and verify the stages between initial and fatal cracking, forms of damage and surface damage to plastic products and/or joints.