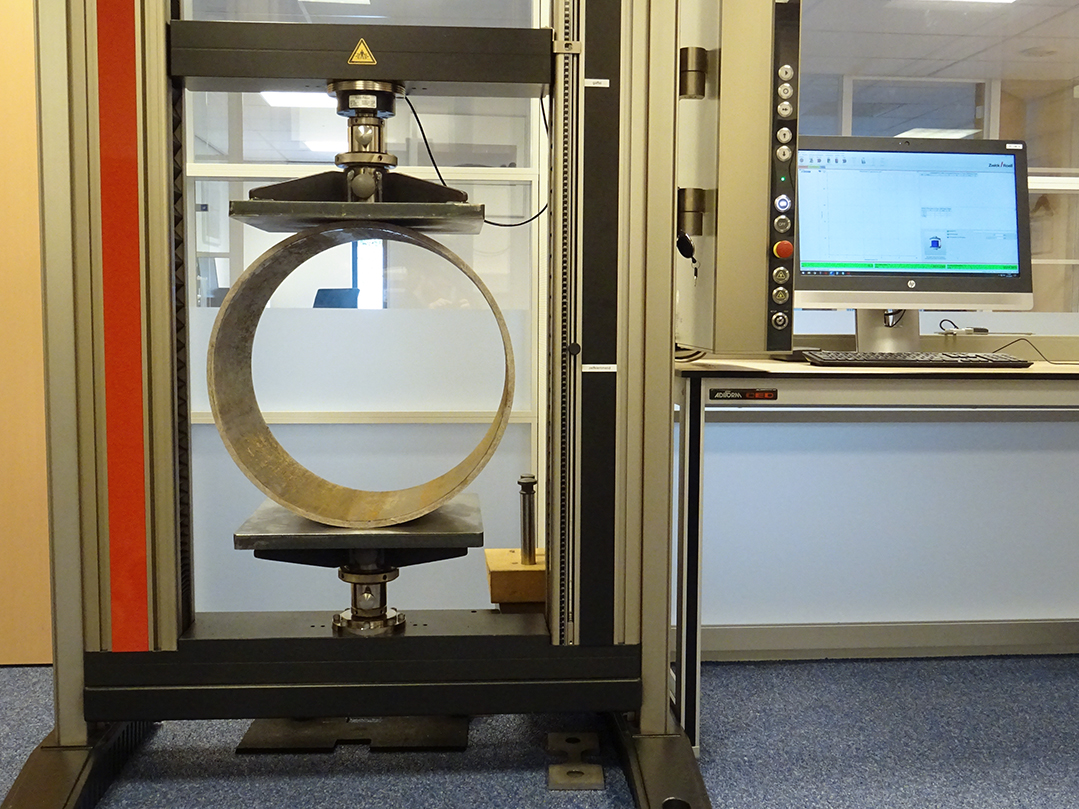

Testing of plastics in compliance with current standards

PVC and PE (press) pipes make up a large part of transport pipelines for gas, drinking water and waste water. Because these pipes have been installed and used since the middle of the last century, the (residual) lifespan of plastic distribution pipes is a growing area of attention for managers. Normec QS has the expertise and research facilities to map the remaining life of piping systems.

The historically estimated period of use of these plastic distribution pipes of 50 years appears to be outdated in some cases. For example, location in a favorable earth layer can significantly extend the service life. On the other hand, vibrations caused by traffic, for example, or unfavourable soil compaction can have critical consequences for the functionality of piping systems.

As in all piping systems, plastic pipe material is subject to degradation processes and environmental influences. Regular degradation processes of a physical, chemical and mechanical nature play a role in slowly decreasing functionality. In addition, pressure and water hammer, but also the action of chemicals from the soil are influence factors that can accelerate degradation. These processes can reduce the reliability of piping systems and result in, for example, leaks or pressure loss.

By making an inventory of the current condition of piping systems, it is possible to predict the remaining life. This allows more targeted investment decisions to be made. In this way, large-scale renewal of the network can make way for replacements at the most crucial locations.