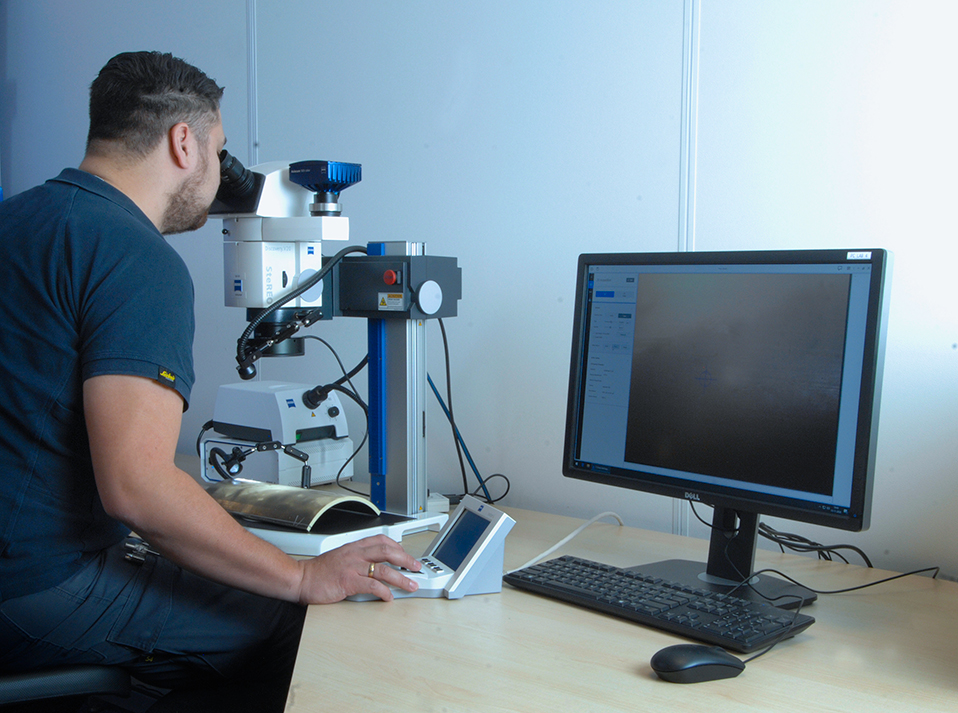

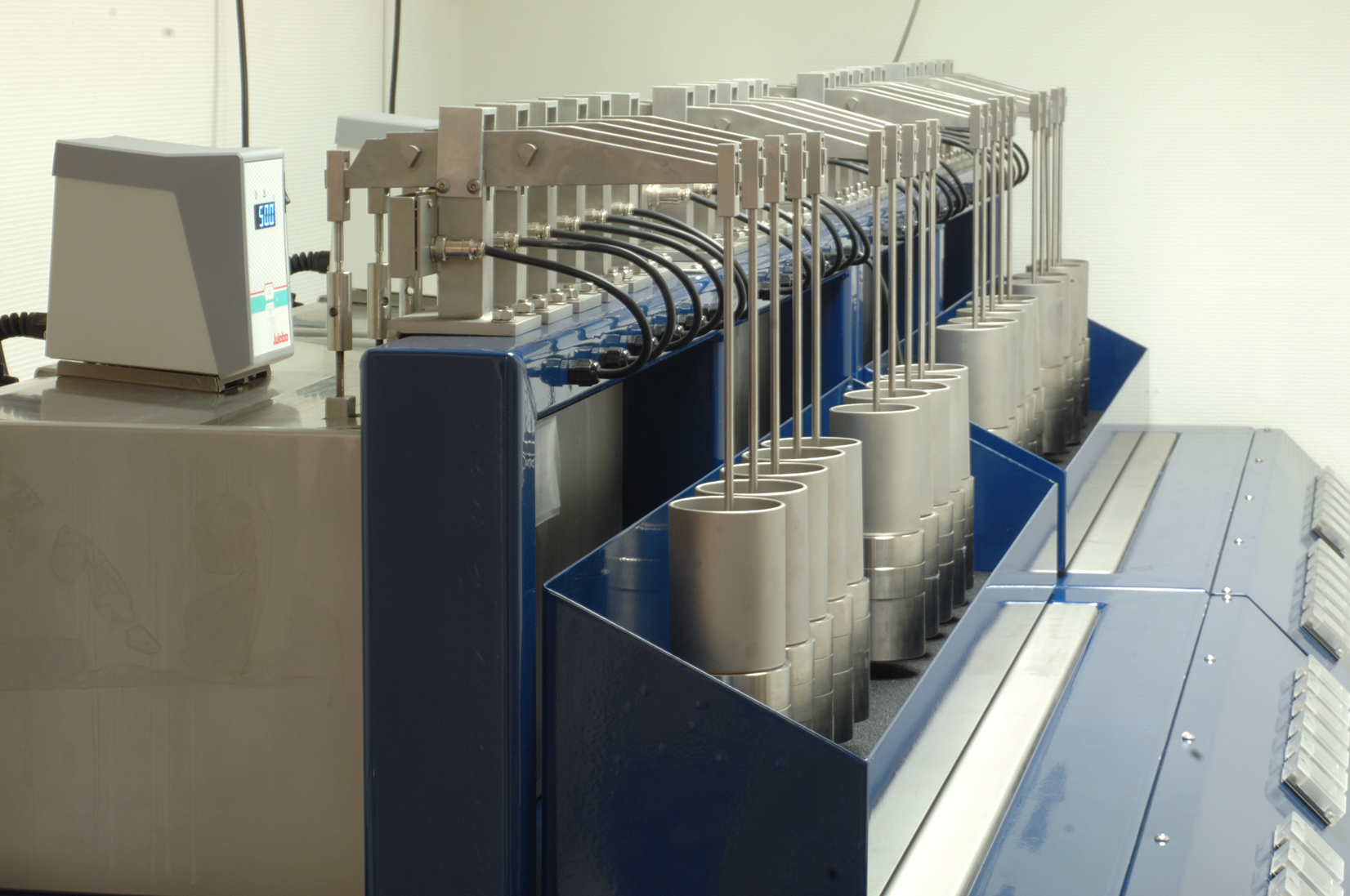

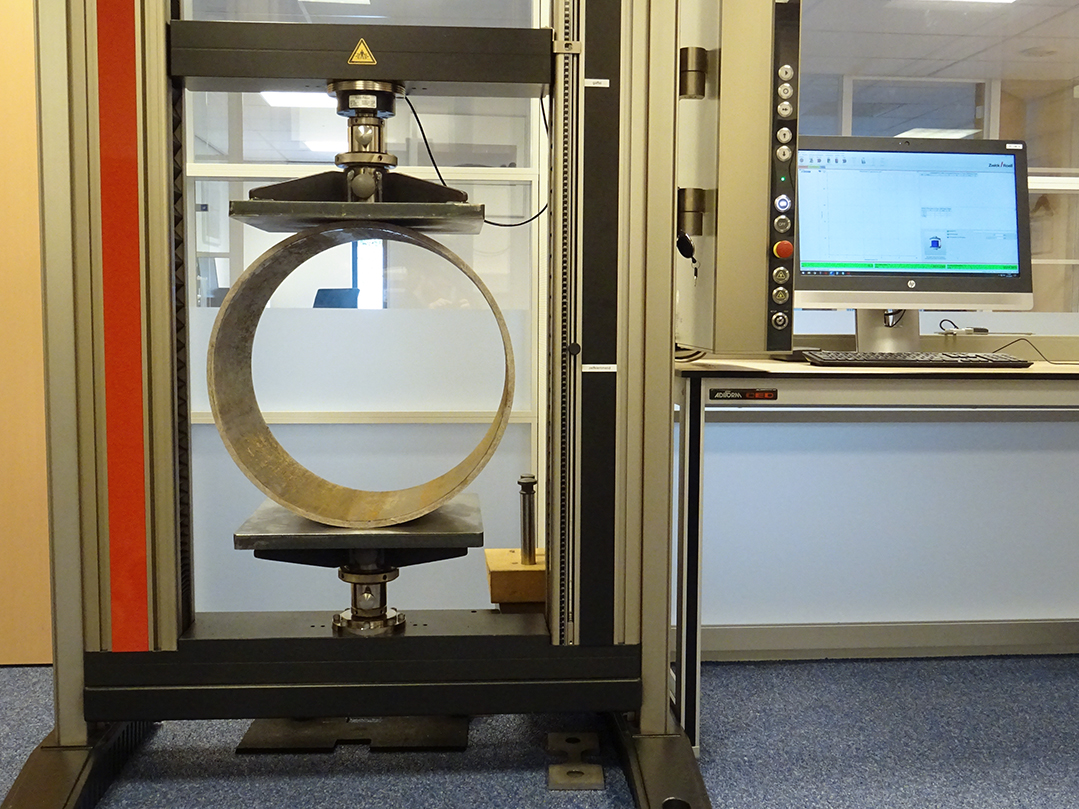

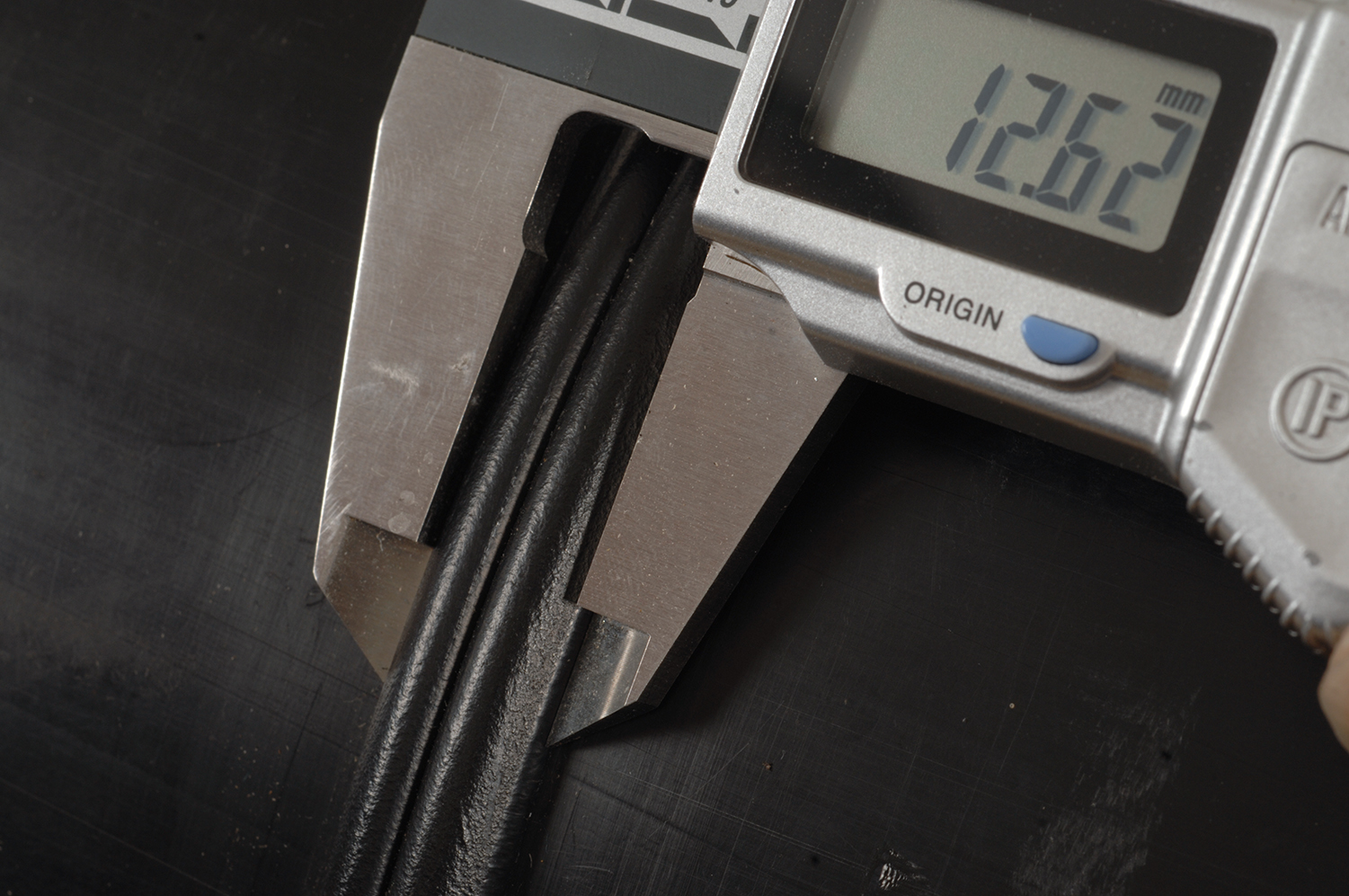

Testing of plastics and welded joints in compliance with current standards

Normec QS focuses within its laboratory on the testing and assessment of plastic materials and welded joints. Normec QS’s laboratory facilities are equipped to test various plastics and plastic compounds in accordance with standardized NEN, EN, ISO, DIN or DVS standards.