Technical service life of PVC pipes

There certainly is. A large proportion of underground PVC pipes are already quite old and approaching the end of their technical lifespan in the coming years. This depends on many factors, such as the environment, but also the quality of the pipes and how long they have been in the ground. Every year, failing pipes cause water wastage and damage to infrastructure leading to prohibitively expensive repairs. A shame, right?

Why is such a condition assessment so important? For pipeline owners and managers such as municipalities and water boards, it is very important to know the status of their pipelines in order to have a better understanding of the risks and thus the costs. Because what happens if cracks or ruptures appear in a PVC pipeline due to ageing, material degradation or, for example, heavy work? Calamities! Both for the consumer, but also the unforeseen costs to repair such damage are incredibly high for pipe operators. Pipes can generally last longer than previously thought, however, a small number of critical spots can cause danger. Precisely those critical spots are important to identify and address by assessing risks and inspecting pipes. In the end, pipeline owners save enormously on costs over the lifetime of the pipeline, which can often be extended as a result. So, on the one hand, to prevent calamities and their consequences and, on the other hand, to reduce the cost of the pipeline over its total lifetime by extending its life.

By identifying the risks in time, inspecting the pipelines preventively and then examining them for material quality, you will have more control over your pipeline network.

This is what happens during the condition assessment of PVC pipelines. HDM Pipelines, Acquaint and QS are working closely together on this specialist issue. They are doing this for the first time and the start of this unique collaboration bodes well. Why? These independent parties complement each other well and each company has its own crucial role in the process. What is their joint strength? The overall picture. Acquaint provides important data of the entire route and QS dives into more depth by conducting material research. HDM translates all this data into concrete information. What is the actual quality of the pipeline network? The reliable results of risk analysis, inspection and quality control are the added value for the customer

HDM Pipelines is a specialist in pipelines and pipe networks. First of all, they identify the risks of the PVC pipelines and give advice on which pipelines should be inspected first, but also which inspection techniques they can best use to do so. This way, the customer immediately knows which pipes they should zoom in on. Based on data from various open data sources, HDM can determine which discharge pipeline has the highest risk of failure and which mitigating measures should be taken to reduce the risk to an acceptable level. This ensures more effective and efficient management and maintenance of the pipeline network!

Acquaint is an expert in internal pressure pipe inspections in the drinking and wastewater sector. They have developed the smart Acquarius tool, which can be used without excavation work and disruption of operations.

With its sensors, Acquarius quickly identifies the condition of drinking and wastewater pipes. And this can be done while a pipeline is still in operation. For example, it measures the healthy remaining wall thickness, deformation, ovality, location, and deviations in the joints of a PVC pipe. All these failure mechanisms can lead to calamities, but so can any angular distortions. Thanks to its manoeuvrability, the Acquarius finds its way everywhere. If one pipeline has been inspected, Acquaint can use the resulting data, combined with other data, to predict the condition of other pipelines without the need for inspection. Ultimately, therefore, there is no need to inspect all pipes. An innovation that is in full swing.

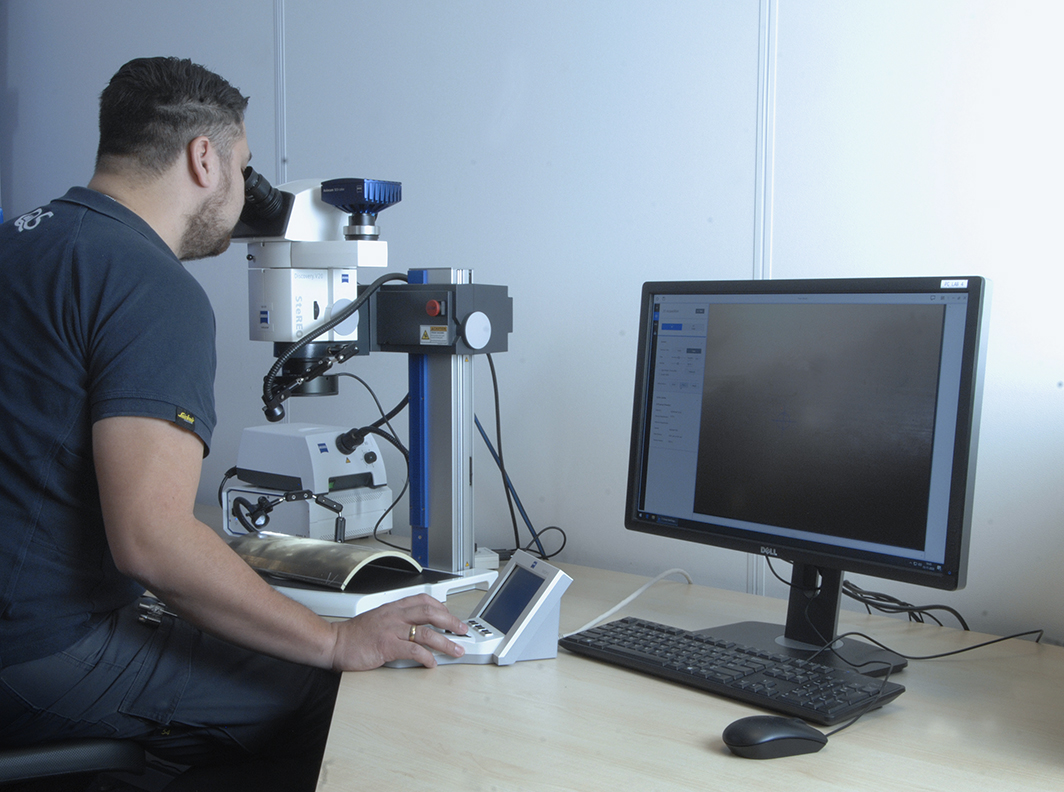

On average, a plastic pipe lasts about 25 to 50 years. But practice shows that these pipes often last (much) longer. And that is interesting for the pipeline manager. QS specialises in quality control and material testing of these plastic piping systems. They have developed a practical, effective and scientifically based research method to determine the degree of ageing. This research takes place in their own laboratory. After Acquaint has carried out the inspection, QS gets to work. Depending on the length of the pipe, one or more sections of plastic pipe are taken out of the ground and scrutinised. The quality of the material, its strength, any micro-cracks and possible chemical attack are examined. The outcome of this examination including interpretation by a recognised long-term behaviour expert is recorded in a final report with a clear conclusion.

Pipeline management without surprises! What are the benefits? Risks are reduced, the safety of the plastic pipelines increased, substantial cost savings through smart management and, as pipeline manager, you have 100% insight into your pipeline network.

All data collected by the cooperation partners QS and Acquaint are used by HDM Pipelines for a residual life analysis of the entire pipeline route. This residual lifespan approach is very important for pipeline owners when investment decisions have to be made in the (near) future. All in all, the combination of fieldwork, material research and the residual life approach to this pipeline enables the pipeline owner to take his pipeline management to the next level. This fits seamlessly with asset management, which has become increasingly popular within this type of organisation in recent years.